Pack battery factory production management system

Welcome to our dedicated page for Pack battery factory production management system! Here, we have carefully selected a range of videos and relevant information about Pack battery factory production management system, tailored to meet your interests and needs. Our services include high-quality home solar systems, photovoltaic panels, and advanced inverters, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Pack battery factory production management system, including cutting-edge home solar systems, advanced photovoltaic panels, and tailored solar energy solutions for a variety of applications. Whether you're looking for residential rooftop installations, commercial solar projects, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

18650 Cell Manufacturing Process, Automatic Production Line

Design Of Battery Management System For Battery Pack Production 18650 Cell Manufacturing Process This video is not original, if there is any infringement, please contact our staff to remove this

WhatsApp Chat

Mastering the Battery Pack Assembly Process: A

From sourcing raw materials to integrating sophisticated battery management systems (BMS), each step in the assembly process plays a

WhatsApp Chat

Key Points of Lithium Battery PACK Manufacturing

The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective

WhatsApp Chat

Battery Module: Manufacturing, Assembly and Test Process Flow.

In this article, we will look at the Module Production part. The Remaining two parts Pack Production and Vehicle Integration will follow in the next articles. 1. Module Production.

WhatsApp Chat

Mastering the Battery Pack Assembly Process: A Comprehensive

From sourcing raw materials to integrating sophisticated battery management systems (BMS), each step in the assembly process plays a critical role in determining the

WhatsApp Chat

Battery Production | AVL

To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End Of Line. From

WhatsApp Chat

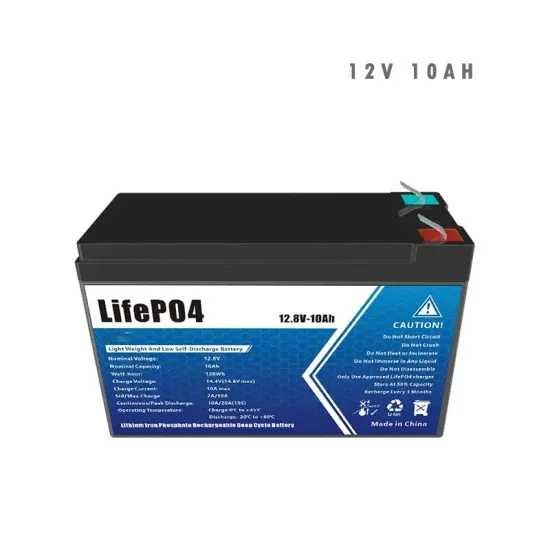

Lithium-ion Battery China Manufacturer/Company/Supplier | Eco

ECO POWER GROUP is a global lithium battery company offering lithium ion batteries, lithium battery energy storage systems and various components. Our team have Innovative

WhatsApp Chat

What is BMS Battery Management System?

A BMS battery management system refers to an electronic system responsible for overseeing the operations of a rechargeable battery.

WhatsApp Chat

Battery Pack Manufacturing Process: Step-by-Step

The final step in the battery pack manufacturing process is the application of the Battery Management System, commonly referred to as

WhatsApp Chat

Top 10 Battery Management System Manufacturers in China

In China, there are many BMS manufacturers. This blog lists the Top 10 battery management system manufacturers in China for your reference.

WhatsApp Chat

Battery Manufacturing | Bosch Manufacturing Solutions | BMG

With over 15 years of experience in battery manufacturing, we specialize in Cell to Pack Manufacturing and Cell Technology solutions for battery modules and packs. Our portfolio

WhatsApp Chat

The EV Battery Manufacturing Process: Step by Step

The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

WhatsApp Chat

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

WhatsApp Chat

Battery Module & Pack Manufacturing: Step-by-Step

Interested in setting up or upgrading your Li-ion battery pack assembly line with smart, scalable turnkey solutions? Contact us to discover

WhatsApp Chat

Lithium-ion Battery Module and Pack Production Line

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment

WhatsApp Chat

Key Points of Lithium Battery PACK Manufacturing

Conclusion The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a

WhatsApp Chat

Key Points of Lithium Battery PACK Manufacturing Process

The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective circuit module (PCM) or battery

WhatsApp Chat

Battery Pack Manufacturing Process

Learn the complete battery pack manufacturing process, from cell selection to final assembly.

WhatsApp Chat

Lithium-ion Battery Module and Pack Production Line

These systems are used to harmonize and connect the various units and equipment to achieve efficient operation of the entire production line

WhatsApp Chat

Quality Assurance – Electrios Consultants

3) Auditors factory inspection 4) Battery Pack/Module/System inspection 4) Final draft report. Lithium-ion Battery factory Quality Assurance Sample Audit Lithium-Ion Battery Manufacturer

WhatsApp Chat

Small-scale Lithium Battery PACK production line plant

The main process flow of a lithium battery PACK production line includes the selection and matching of battery cells, the assembly of battery modules, the welding of cells, the integration

WhatsApp Chat

Lithium-ion Battery Module and Pack Production Line Process Flow

These systems are used to harmonize and connect the various units and equipment to achieve efficient operation of the entire production line and management of

WhatsApp Chat

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

WhatsApp Chat

Battery Pack Manufacturing Process: Step-by-Step Guide

The final step in the battery pack manufacturing process is the application of the Battery Management System, commonly referred to as BMS. This crucial system plays a

WhatsApp Chat

Battery Module: Manufacturing, Assembly and Test

In this article, we will look at the Module Production part. The Remaining two parts Pack Production and Vehicle Integration will follow in the

WhatsApp Chat

Battery Module & Pack Manufacturing: Step-by-Step

Interested in setting up or upgrading your Li-ion battery pack assembly line with smart, scalable turnkey solutions? Contact us to discover how our equipment partners can

WhatsApp Chat

EV Battery Production. Optimized.

Our tailored MES for battery is built to manage hybrid production. So you can take a simpler and apply one, integrated and information-enabled across your operations. A typical gigafactory

WhatsApp Chat

WEG Battery Energy Storage System (BESS)

Battery System Support and Engineering BOP - Balance of Plant At the heart of WEG''s BESS solution is an advanced energy control and management

WhatsApp Chat

Battery Manufacturing | Battery Solutions | ABB

ABB Plant Optimization Methodology delivers optimized design, project execution excellence, and efficient ongoing operations for battery manufacturers.

WhatsApp ChatFAQs 6

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

What is a battery pack assembly process?

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

What is a battery management system?

Assembling battery cells into modules, interconnecting these modules, and applying a sophisticated Battery Management System enable these battery packs to power an extensive range of applications across various industries.

Related reading topics

- India Large Energy Storage Cabinet Customization

- Brazilian home photovoltaic panel manufacturers

- Inverter 60v 100a to 220v

- How to connect flywheel energy storage

- Is there a direction for lithium phosphate battery packs

- Communication green base station energy storage cabinet debugging

- Solar grid-connected inverter 5kw

- South Korea Photovoltaic Power Plant Power Generation BESS Company

- New energy battery cabinet charging cycle principle

- Outdoor Brand Solar Photovoltaic On-site Energy

- The service life of large energy storage power stations

- Sao Tome and Principe switches to photovoltaic site energy

- How much does a portable energy storage power supply cost in Bangladesh

- Indonesia Energy Storage Power Station Planning

- South Africa s new energy national energy battery cabinet

- Kazakhstan s new solar power generation system for home use

- Sunroom photovoltaic panel manufacturer